Properties

8630 is a low-alloy steel primarily composed of nickel, chromium, and molybdenum, which gives it good toughness, strength, and hardenability. Its mechanical properties make this steel grade highly suitable for components that require excellent strength and impact resistance, like gears and fasteners. 8630 can also be heat-treated to further increase its strength and hardness.

| Chemical Properties | |

|---|---|

| Carbon | 0.28 – 0.33 |

| Manganese | 0.70 – 0.90 |

| Silicon | 0.15 – 0.35 |

| Chromium | 0.40 – 0.60 |

| Nickel | 0.40 – 0.70 |

| Molybdenum | 0.15 – 0.25 |

| Phosporus | 0.035 (max) |

| Sulfur | 0.04 (max) |

Shapes & Sizes Available

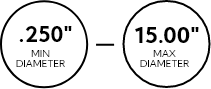

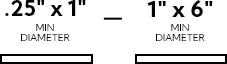

- Rounds

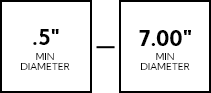

- Square

- Round Corner Square

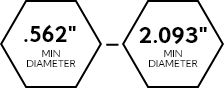

- Hex

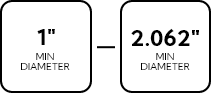

- Flats

Requirement Specifications we can meet:

- ASTM A29

- ASTM A320L7

- ASTM A322

- ASTM A829

- ASTM A108

- ASTM A449