Properties

300 series stainless steel is known for its corrosion resistance and exceptional formability. It’s commonly used in food processing equipment, chemical containers, and architectural elements because it offers excellent durability. This stainless steel series is also non-magnetic and can maintain integrity even under high temperatures, so they’re also ideal for medical instruments and aerospace components.

The list below is just a generalized overview—the chemical composition will vary based on the specific grade within the 300 series.

| Chemical Properties | |

|---|---|

| Chromium | 16 – 20 |

| Nickel | 8 – 14 |

| Molybdenum | 3 (max) (for grade 316 only) |

| Carbon | 0.03 – 0.08 (max) |

| Manganese | 2 |

| Phosphorus | 0.045 (max) |

| Sulfur | 0.03 (max) |

| Silicon | 0.75 (max) |

| Nitrogen | 0.1 |

Shapes & Sizes Available

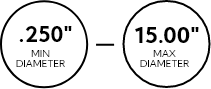

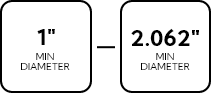

- Rounds

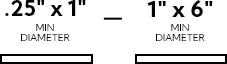

- Flats

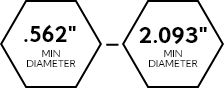

- Hex

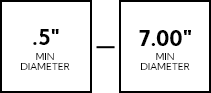

- Square

- Round Corner Square