Properties

1215 steel is re-sulfurized and re-phosphorized free-machining steel commonly used in applications that require fast machining and bright finishes. Its excellent machinability is its most prominent feature, thanks to the added sulfur and phosphorus, which form inclusions in the steel to aid in chip breaking during the machining process.

This grade is ideally suited for parts that require extensive machining, such as screws, nuts, bolts, and other fasteners. The steel’s chemical composition enhances its cutting properties but compromises its weldability, so it’s often used in parts where intricate drilling and cutting are more crucial than the ability to be welded.

| Chemical Properties | |

|---|---|

| Iron | 98.42 – 98.95 |

| Carbon | 0.09 (max) |

| Manganese | 0.75 – 1.05 |

| Phosporus | 0.04 – 0.09 |

| Sulfur | 0.26 – 0.35 |

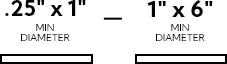

Shapes & Sizes Available

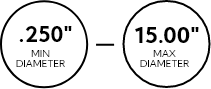

- Rounds

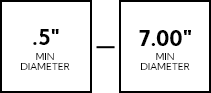

- Square

- Round Corner Square

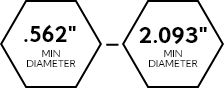

- Hex

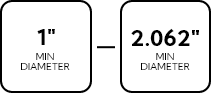

- Flats

Requirement Specifications We Can Meet:

- ASTM A576

- ASTM A108