Properties

1060 steel, characterized by its high carbon content, offers notable strength and hardness. It’s primarily used to manufacture tools and products like springs and hand tools because it can maintain a sharp edge. The steel’s composition also ensures a good mix of toughness and flexibility, key for items needing impact resistance. However, its carbon level reduces its ductility and welding ease compared to steels with lower carbon content.

| Chemical Properties | |

|---|---|

| Iron | 98.35 – 98.85 |

| Carbon | 0.55 – 0.65 |

| Manganese | 0.60 – 0.90 |

| Phosporus | 0.04 (max) |

| Sulfur | 0.05 (max) |

Shapes & Sizes Available

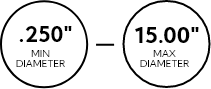

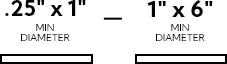

- Rounds

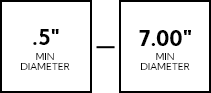

- Square

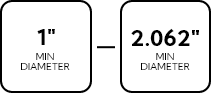

- Round Corner Square

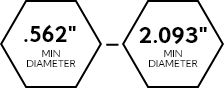

- Hex

- Flats

Requirement Specifications We Can Meet:

- ASTM A576