Properties

1050 steel is a high carbon, “plain” carbon steel known for its high strength and hardness, particularly when heat treated. Its carbon content (approximately 0.50%) makes it suitable for applications requiring strength and durability, including machinery parts, cold-headed fasteners, and shafts.

Although 1050 is known for its combination of strength and elasticity, its higher carbon content means it is not as easy to work with or weld as lower carbon steel grades, so it’s often used where strength and durability are more critical than weldability or formability.

| Chemical Properties | |

|---|---|

| Iron | 98.46 – 98.92 |

| Carbon | 0.48 – 0.55 |

| Manganese | 0.60 – 0.90 |

| Phosporus | 0.04 (max) |

| Sulfur | 0.05 (max) |

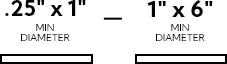

Shapes & Sizes Available

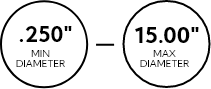

- Rounds

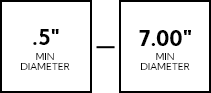

- Square

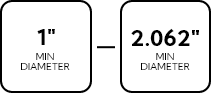

- Round Corner Square

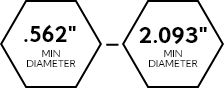

- Hex

- Flats

Requirement Specifications We Can Meet:

- ASTM A576

- ASTM A108